Top 10 Industrial IoT (IIoT) Use Cases Revolutionizing Manufacturing

January 30, 2026

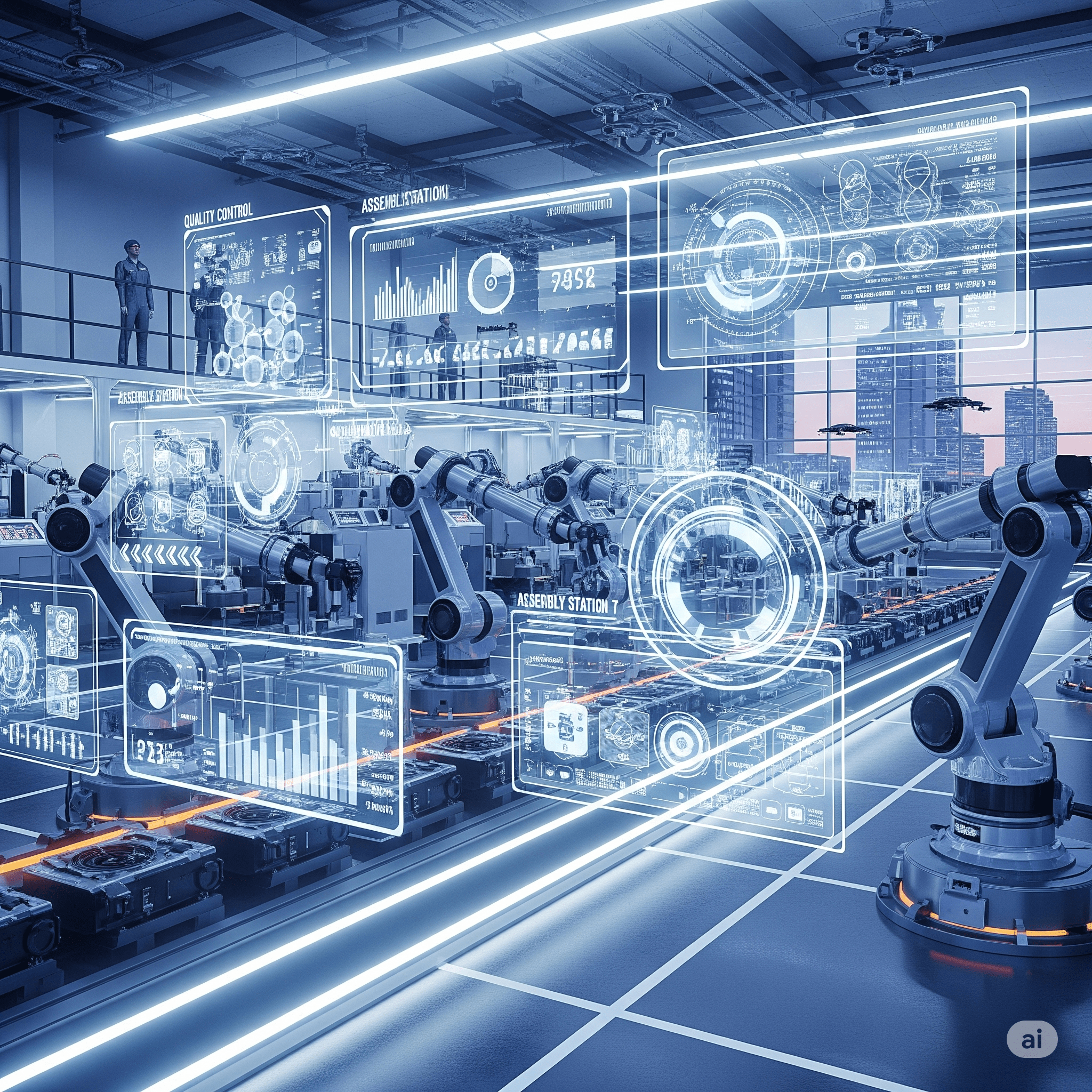

How IIoT is Transforming Modern Industry

The Industrial Internet of Things (IIoT) is the application of IoT technology to the manufacturing and industrial sectors. It involves connecting machinery, sensors, and enterprise systems to collect, analyze, and act upon vast amounts of data in real-time. This connectivity is fueling the "Fourth Industrial Revolution," or Industry 4.0, leading to unprecedented gains in efficiency, safety, and innovation.

The Core Value of IIoT

IIoT bridges the gap between the physical operational technology (OT) on the factory floor and the digital information technology (IT) of the enterprise. This integration provides a unified, real-time view of operations, enabling data-driven decision-making at every level.

The Top 10 IIoT Applications

| Rank | Use Case | Description | Key Benefits |

|---|---|---|---|

| 1 | Predictive Maintenance | Sensors monitor equipment (vibration, temperature, power draw) to predict failures before they happen, allowing for proactive maintenance. | Reduced downtime, lower repair costs, increased asset lifespan |

| 2 | Real-time Asset Tracking | GPS and RFID/BLE tags track the location and status of tools, equipment, and inventory within the factory and across the supply chain. | Improved asset utilization, reduced theft/loss, optimized workflows |

| 3 | Supply Chain Optimization | End-to-end visibility from raw material sourcing to final delivery, monitoring location, temperature, and handling of goods in transit. | Increased efficiency, reduced spoilage, improved delivery times |

| 4 | Energy Management | Smart meters and sensors monitor energy consumption of individual machines and entire facilities to identify waste and optimize usage. | Lower energy costs, reduced carbon footprint, improved sustainability |

| 5 | Digital Twins | A virtual model of a physical asset or process, updated with real-time sensor data. Used for simulation, analysis, and optimization. | Faster prototyping, risk-free testing, improved process design |

| 6 | Connected Worker Safety | Wearable sensors monitor workers' health, location, and exposure to hazardous environments (gases, noise), triggering alerts in emergencies. | Enhanced safety, faster emergency response, improved compliance |

| 7 | Quality Control & Vision | AI-powered cameras and sensors inspect products on the assembly line, detecting defects far more accurately and quickly than human eyes. | Reduced defects, improved product quality, lower scrap rates |

| 8 | Remote Operations & Control | Enables engineers to monitor and control machinery in remote or hazardous locations (e.g., oil rigs, mines) from a central control room. | Increased operational efficiency, improved worker safety |

| 9 | Smart Metering & Billing | Automated utility meters (water, gas, electricity) that provide real-time usage data for accurate billing and demand forecasting. | Eliminates manual readings, enables dynamic pricing, improves accuracy |

| 10 | Process Automation & SCADA | Integrating OT systems like PLCs and SCADA with IT systems via protocols like MQTT to enable more intelligent, data-driven automation rules. | Increased production speed, improved consistency, greater flexibility |

The Role of MQTT in IIoT

MQTT has become a dominant protocol in IIoT for several key reasons:

- Lightweight: It can run on resource-constrained industrial controllers and sensors.

- Bandwidth-Efficient: It minimizes network usage, which is crucial in large factory environments with thousands of devices.

- Reliable: Its QoS levels ensure that critical command-and-control messages are delivered.

- Decoupled: The pub/sub model allows new sensors, machines, and applications to be added to the system without reconfiguring existing components.

As industries continue their digital transformation, IIoT will be the engine driving innovation. By connecting every aspect of the industrial process, companies can unlock new levels of productivity, create safer working environments, and build the smart factories of the future.